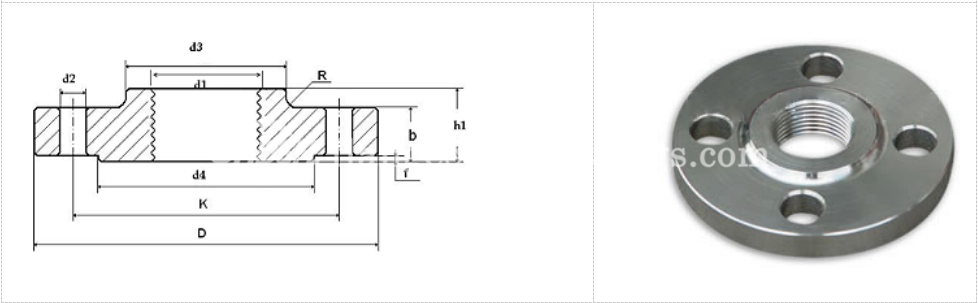

EN 1092-1 TYPE 13 THREADED FLANGE

PN6, PN10, PN16, PN25, PN40

Mga Dimensyon sa Flange ug Gibanabana nga Masa

| EN 1092-1 TYPE 13 PN6 THREADED FLANGE | |||||||||||||

| Gi-rate nga Diametro | Flange | Liog | Gipataas ang nawong | Mga tornilyo | Gibug-aton | ||||||||

| d1 | Thread | k | D | b | h1 | d3 | d4 | f | d2 | Thread | Mga buho sa bolt | KG | |

| 15 | 21,3 | R 1/2″ | 55 | 80 | 12 | 20 | 30,0 | 40,0 | 2,0 | 11 | M10 | 4 | 0,373 |

| 20 | 26,9 | R 3/4″ | 65 | 90 | 14 | 24 | 40,0 | 50,0 | 2,0 | 11 | M10 | 4 | 0,584 |

| 25 | 33,7 | R 1″ | 75 | 100 | 14 | 24 | 50,0 | 60,0 | 2,0 | 11 | M10 | 4 | 0,729 |

| 32 | 42,4 | R 1-1/4″ | 90 | 120 | 14 | 26 | 60,0 | 70,0 | 2,0 | 14 | M12 | 4 | 1,040 |

| 40 | 48,3 | R 1-1/2″ | 100 | 130 | 14 | 26 | 70,0 | 80,0 | 3,0 | 14 | M12 | 4 | 1,200 |

| 50 | 60,3 | R 2″ | 110 | 140 | 14 | 28 | 80,0 | 90,0 | 3,0 | 14 | M12 | 4 | 1,340 |

| 65 | 76,1 | R 2-1/2″ | 130 | 160 | 14 | 32 | 100,0 | 110,0 | 3,0 | 14 | M12 | 4 | 1,830 |

| 80 | 88,9 | R 3" | 150 | 190 | 16 | 34 | 110,0 | 128,0 | 3,0 | 18 | M16 | 4 | 2,750 |

| 100 | 114,3 | R 4" | 170 | 210 | 16 | 40 | 130,0 | 148,0 | 3,0 | 18 | M16 | 4 | 3,010 |

| 125 | 139,7 | R 5" | 200 | 240 | 18 | 44 | 160,0 | 178,0 | 3,0 | 18 | M16 | 8 | 4,300 |

| 150 | 168,3 | R 6" | 225 | 265 | 18 | 44 | 185,0 | 202,0 | 3,0 | 18 | M16 | 8 | 4,630 |

| 1. SURFACE FINISH NGA NAG-ATUBANG SA TYPES A, B1, B2 etc | |||||||||||||

| 2. FLANGE MARKING: LOGO EN 1092-1 / 13 / DN100 / PN6 / P245GH / HEAT NUMBER | |||||||||||||

| EN 1092-1 TYPE 13 PN16 THREADED FLANGE | |||||||||||||

| Gi-rate nga Diametro | Flange | Liog | Gipataas ang nawong | Mga tornilyo | Gibug-aton | ||||||||

| d1 | Thread | k | D | b | h1 | d3 | d4 | f | d2 | Thread | Mga buho sa bolt | KG | |

| 15 | 21,3 | R 1/2″ | 65 | 95 | 16 | 22 | 35,0 | 45,0 | 2,0 | 14 | M12 | 4 | 0,722 |

| 20 | 26,9 | R 3/4″ | 75 | 105 | 18 | 26 | 45,0 | 58,0 | 2,0 | 14 | M12 | 4 | 1,040 |

| 25 | 33,7 | R 1″ | 85 | 115 | 18 | 28 | 52,0 | 68,0 | 2,0 | 14 | M12 | 4 | 1,250 |

| 32 | 42,4 | R 1-1/4″ | 100 | 140 | 18 | 30 | 60,0 | 78,0 | 2,0 | 18 | M16 | 4 | 1,810 |

| 40 | 48,3 | R 1-1/2″ | 110 | 150 | 18 | 32 | 70,0 | 88,0 | 3,0 | 18 | M16 | 4 | 2,060 |

| 50 | 60,3 | R 2″ | 125 | 165 | 18 | 28 | 84,0 | 102,0 | 3,0 | 18 | M16 | 4 | 2,390 |

| 65 | 76,1 | R 2-1/2″ | 145 | 185 | 18 | 32 | 104,0 | 122,0 | 3,0 | 18 | M16 | 4 | 2,970 |

| 80 | 88,9 | R 3" | 160 | 200 | 20 | 34 | 118,0 | 138,0 | 3,0 | 18 | M16 | 8 | 3,780 |

| 100 | 114,3 | R 4" | 180 | 220 | 20 | 40 | 140,0 | 158,0 | 3,0 | 18 | M16 | 8 | 4,380 |

| 125 | 139,7 | R 5" | 210 | 250 | 22 | 44 | 168,0 | 188,0 | 3,0 | 18 | M16 | 8 | 6,070 |

| 150 | 168,3 | R 6" | 240 | 285 | 22 | 44 | 195,0 | 212,0 | 3,0 | 22 | M20 | 8 | 7,240 |

| 1. SURFACE FINISH NGA NAG-ATUBANG SA TYPES A, B1, B2 etc | |||||||||||||

| 2. FLANGE MARKING: LOGO EN 1092-1 / 13 / DN100 / PN16 / P245GH / HEAT NUMBER | |||||||||||||

Kapasidad sa Produksyon ug Mga Detalye sa Pagpamalit

1. Suplay Flange Dimensyon DN15 – DN2000 (1/2″ – 80″), Forged Flange.

2. Materyal nga Carbon Steel: P235GH, P245GH, P250GH, RST37.2, C22.8, S235JR, ST37, ASTM A105

3. Materyal nga Stainless Steel: ASTM A182 F304, F304L, F316, F316L, F321 ug uban pa.

4. Flanges Anti Rust: Anti Rust Oil, Black Paint, Yellow Paint Coating, Hot Dipped Galvanized, Cold Galvanized etc.

5. Buwan nga Output: 3000 ka tonelada kada Bulan.

6. Mga Termino sa Paghatud: CIF, CFR, FOB, EXW.

7. Mga Termino sa Pagbayad: Wire Transfer (T/T), Irrevocable L/C at Sight etc.

8. Minimum Order Quantity: 1Ton o 100Pcs.

9. Garantiya sa Kalidad: EN10204 3.1 Sertipiko, Sertipiko sa Mill, Inspeksyon sa Ikatulong Partido, Libre nga Serbisyo sa Pagpuli.

10. Pangitag Dugang nga mga Kinahanglanon Sa Flanges Market.