BS 10 TABLE D FLANGE

British Standard BS 10: 1962 – Espesipikasyon para sa Flanges ug Bolting para sa Pipe, Valves, ug Fittings.Kini naglangkob sa yano, boss, integrally cast o forged, ug welding liog matang flanges, sa napulo ka mga lamesa.Bisan kung ang BS 10 kay obsolescent, kini nagpabilin nga gigamit alang sa mga sukat sa gaan nga katungdanan, ekonomiya nga stainless steel flanges sa mga aplikasyon diin ang resistensya sa kaagnasan ug / o kahinlo, imbes nga taas nga presyur ug temperatura, mao ang panguna nga mga konsiderasyon.Ang mga musunod nga mga lamesa nagdetalye sa magamit nga sukaranan nga mga sukat gikan sa mga Talaan D, E, F ug H sa BS 10.

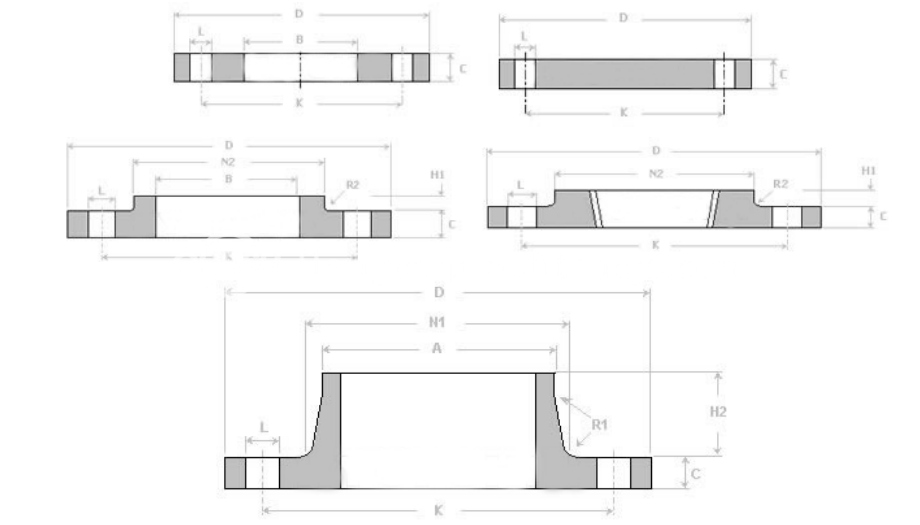

Mga Dimensyon sa Flange ug Gibanabana nga Masa

| BRITISH BS 10 TABLE D FLANGE SPECIFICATION | ||||||||||||||

| NB SIZE | D | K | L | A | C | N1 | N2 | B | H1 | H2 | R1 | R2 | MGA BUTANG | |

| IN | mm |

|

|

|

|

|

|

|

|

|

|

|

|

|

| ½” | 15 | 95.3 | 66.8 | 14.5 | 21.3 | 4.8 | 27.0 | 33.3 | 22.4 | 9.5 | 22.2 | 6.4 | 1.6 | 4 |

| ¾” | 20 | 101.6 | 73.2 | 14.5 | 26.7 | 4.8 | 33.3 | 38.1 | 27.7 | 11.1 | 22.2 | 6.4 | 1.6 | 4 |

| 1″ | 25 | 114.3 | 82.6 | 14.5 | 33.5 | 4.8 | 42.9 | 47.6 | 34.6 | 11.1 | 22.2 | 6.4 | 1.6 | 4 |

| 1 ¼” | 32 | 120.7 | 87.4 | 14.5 | 42.2 | 6.4 | 49.2 | 55.6 | 43.2 | 11.1 | 25.4 | 6.4 | 1.6 | 4 |

| 1 ½” | 40 | 133.4 | 98.6 | 14.5 | 48.3 | 6.4 | 58.7 | 61.9 | 49.5 | 12.7 | 28.6 | 6.4 | 1.6 | 4 |

| 2″ | 50 | 152.4 | 114.3 | 17.5 | 60.5 | 7.9 | 69.9 | 74.6 | 62.0 | 12.7 | 28.6 | 6.4 | 1.6 | 4 |

| 2 ½” | 65 | 165.1 | 127.0 | 17.5 | 73.2 | 7.9 | 82.6 | 90.5 | 74.7 | 15.9 | 31.8 | 6.4 | 1.6 | 4 |

| 3″ | 80 | 184.2 | 146.1 | 17.5 | 88.9 | 9.7 | 101.6 | 106.4 | 90.7 | 15.9 | 34.9 | 6.4 | 1.6 | 4 |

| 3 ½” | 88 | 203.2 | 165.1 | 17.5 | 101.6 | 9.7 | 114.3 | 119.1 | 103.4 | 17.5 | 34.9 | 6.4 | 1.6 | 4 |

| 4″ | 100 | 215.9 | 177.8 | 17.5 | 114.3 | 9.7 | 130.2 | 133.4 | 116.1 | 19.1 | 41.3 | 9.5 | 3.2 | 4 |

| 5″ | 125 | 254.0 | 209.6 | 17.5 | 141.2 | 12.7 | 152.4 | 160.3 | 143.8 | 19.1 | 44.5 | 9.5 | 3.2 | 8 |

| 6″ | 150 | 279.4 | 235.0 | 17.5 | 168.4 | 12.7 | 184.2 | 185.7 | 171.7 | 19.1 | 47.6 | 9.5 | 3.2 | 8 |

| 8″ | 200 | 336.6 | 292.1 | 17.5 | 219.2 | 12.7 | 241.3 | 241.3 | 221.5 | 22.2 | 50.8 | 9.5 | 3.2 | 8 |

| 10″ | 250 | 406.4 | 355.6 | 22.2 | 273.1 | 16.0 | 292.1 | 298.5 | 276.4 | 27.0 | 63.5 | 9.5 | 3.2 | 8 |

| 12″ | 300 | 457.2 | 406.4 | 22.2 | 323.9 | 19.1 | 342.9 | 349.3 | 325.9 | 28.6 | 69.9 | 9.5 | 4.8 | 12 |

| 14″ | 350 | 527.1 | 469.9 | 25.4 | 355.6 | 22.2 | 406.4 | - | 359.2 | - | 73.0 | 9.5 | 4.8 | 12 |

| 16″ | 400 | 577.9 | 520.7 | 25.4 | 406.4 | 22.2 | - | - | 410.5 | - | - | - | - | 12 |

| 18″ | 450 | 641.4 | 584.2 | 25.4 | 457.2 | 25.4 | - | - | 461.8 | - | - | - | - | 12 |

| 20″ | 500 | 704.9 | 641.4 | 25.4 | 508.0 | 28.6 | - | - | 513.1 | - | - | - | - | 16 |

| 24″ | 600 | 825.5 | 755.7 | 28.7 | 609.6 | 31.8 | - | - | 616.0 | - | - | - | - | 16 |

Kapasidad sa Produksyon ug Mga Detalye sa Pagpalit.

1.Supply Flange Dimension DN15 – DN2000 (1/2″ – 80″), Forged Flange.

2.Materyal nga Carbon Steel: ASTM A105, S235JR, C22.8, RST37.2, ST37, P245GH, P250GH, ASTM A181, Q235

3.Materyal nga Stainless Steel: ASTM A182 F304, F304L, F316, F316L, F321 ug uban pa.

4.Flanges Anti Rust: Anti Rust Oil, Black Paint, Yellow Paint Coating, Hot Dipped Galvanized, Cold Galvanized etc.

5.Bulanan nga Output: 3000 ka tonelada kada Bulan.

6. Mga Termino sa Paghatud: CIF, CFR, FOB, EXW.

7.Mga Termino sa Pagbayad: Wire Transfer (T / T), Irrevocable L / C sa Sight etc.

8.Minimum Order Quantity: 1Ton o 100Pcs.

9.Quality Guarantee: EN10204 3.1 Certificate, Mill Certificate, Third Party Inspection, Free Replacement Service.

10. Pangitaa ang Dugang nga mga Kinahanglanon Sa Flanges Market.

| BRITISH BS 10 TABLE D FLANGE SPECIFICATION | ||||||||||||||

| NB SIZE | D | K | L | A | C | N1 | N2 | B | H1 | H2 | R1 | R2 | MGA BUTANG | |

| IN | mm |

|

|

|

|

|

|

|

|

|

|

|

|

|

| ½” | 15 | 95.3 | 66.8 | 14.5 | 21.3 | 4.8 | 27.0 | 33.3 | 22.4 | 9.5 | 22.2 | 6.4 | 1.6 | 4 |

| ¾” | 20 | 101.6 | 73.2 | 14.5 | 26.7 | 4.8 | 33.3 | 38.1 | 27.7 | 11.1 | 22.2 | 6.4 | 1.6 | 4 |

| 1″ | 25 | 114.3 | 82.6 | 14.5 | 33.5 | 4.8 | 42.9 | 47.6 | 34.6 | 11.1 | 22.2 | 6.4 | 1.6 | 4 |

| 1 ¼” | 32 | 120.7 | 87.4 | 14.5 | 42.2 | 6.4 | 49.2 | 55.6 | 43.2 | 11.1 | 25.4 | 6.4 | 1.6 | 4 |

| 1 ½” | 40 | 133.4 | 98.6 | 14.5 | 48.3 | 6.4 | 58.7 | 61.9 | 49.5 | 12.7 | 28.6 | 6.4 | 1.6 | 4 |

| 2″ | 50 | 152.4 | 114.3 | 17.5 | 60.5 | 7.9 | 69.9 | 74.6 | 62.0 | 12.7 | 28.6 | 6.4 | 1.6 | 4 |

| 2 ½” | 65 | 165.1 | 127.0 | 17.5 | 73.2 | 7.9 | 82.6 | 90.5 | 74.7 | 15.9 | 31.8 | 6.4 | 1.6 | 4 |

| 3″ | 80 | 184.2 | 146.1 | 17.5 | 88.9 | 9.7 | 101.6 | 106.4 | 90.7 | 15.9 | 34.9 | 6.4 | 1.6 | 4 |

| 3 ½” | 88 | 203.2 | 165.1 | 17.5 | 101.6 | 9.7 | 114.3 | 119.1 | 103.4 | 17.5 | 34.9 | 6.4 | 1.6 | 4 |

| 4″ | 100 | 215.9 | 177.8 | 17.5 | 114.3 | 9.7 | 130.2 | 133.4 | 116.1 | 19.1 | 41.3 | 9.5 | 3.2 | 4 |

| 5″ | 125 | 254.0 | 209.6 | 17.5 | 141.2 | 12.7 | 152.4 | 160.3 | 143.8 | 19.1 | 44.5 | 9.5 | 3.2 | 8 |

| 6″ | 150 | 279.4 | 235.0 | 17.5 | 168.4 | 12.7 | 184.2 | 185.7 | 171.7 | 19.1 | 47.6 | 9.5 | 3.2 | 8 |

| 8″ | 200 | 336.6 | 292.1 | 17.5 | 219.2 | 12.7 | 241.3 | 241.3 | 221.5 | 22.2 | 50.8 | 9.5 | 3.2 | 8 |

| 10″ | 250 | 406.4 | 355.6 | 22.2 | 273.1 | 16.0 | 292.1 | 298.5 | 276.4 | 27.0 | 63.5 | 9.5 | 3.2 | 8 |

| 12″ | 300 | 457.2 | 406.4 | 22.2 | 323.9 | 19.1 | 342.9 | 349.3 | 325.9 | 28.6 | 69.9 | 9.5 | 4.8 | 12 |

| 14″ | 350 | 527.1 | 469.9 | 25.4 | 355.6 | 22.2 | 406.4 | - | 359.2 | - | 73.0 | 9.5 | 4.8 | 12 |

| 16″ | 400 | 577.9 | 520.7 | 25.4 | 406.4 | 22.2 | - | - | 410.5 | - | - | - | - | 12 |

| 18″ | 450 | 641.4 | 584.2 | 25.4 | 457.2 | 25.4 | - | - | 461.8 | - | - | - | - | 12 |

| 20″ | 500 | 704.9 | 641.4 | 25.4 | 508.0 | 28.6 | - | - | 513.1 | - | - | - | - | 16 |

| 24″ | 600 | 825.5 | 755.7 | 28.7 | 609.6 | 31.8 | - | - | 616.0 | - | - | - | - | 16 |